Insight | Tapered Roller Grinding #2 What's the Trick to Centerless Grinding?

2. What's the Trick to Centerless Grinding?

: It's reducing centerline changes.

But you know what?

There are various methods of centerless grinding, and important considerations to keep in mind during the grinding process.

In this follow-up post, we will learn about centerless grinding and the key points briefly.

Let's dive in right now!

What is Centerless Grinding?

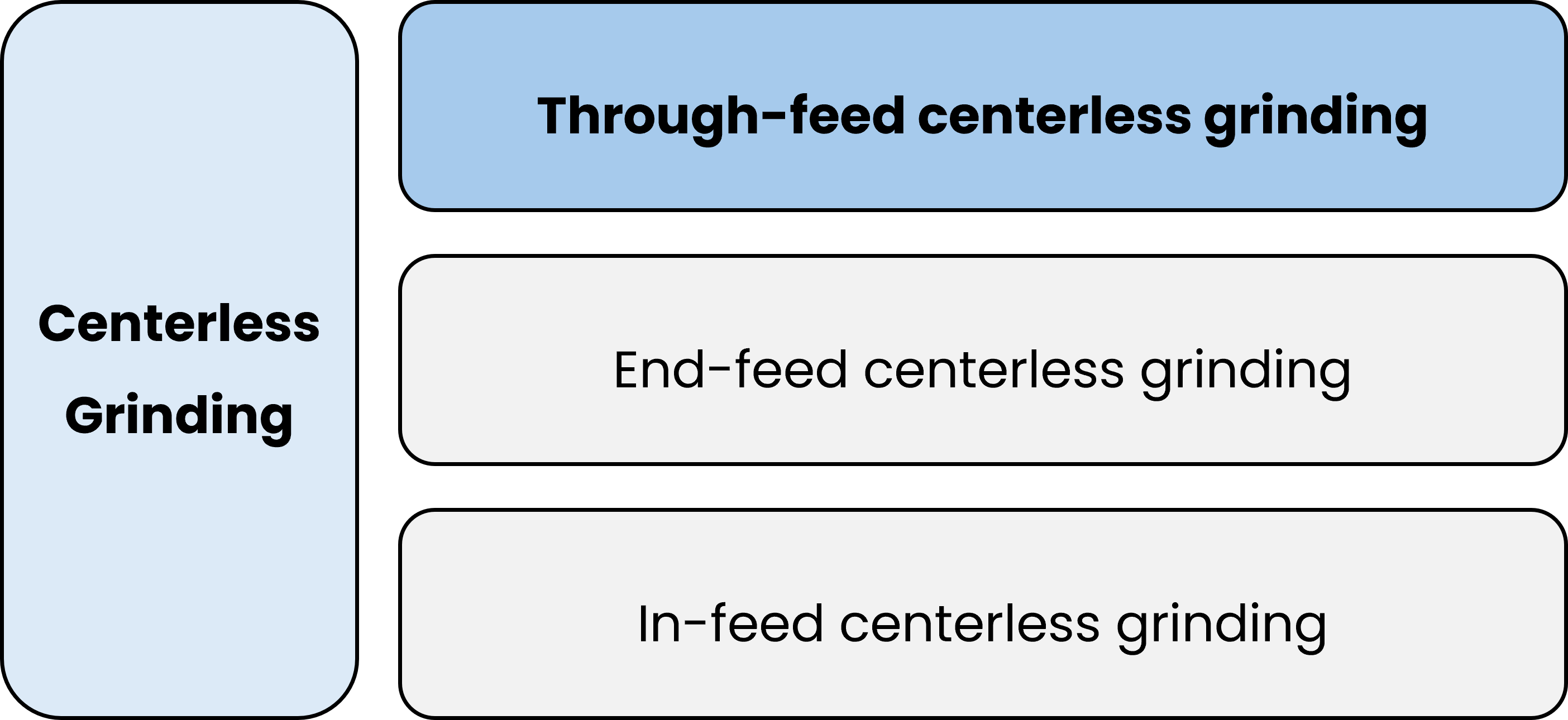

There are three types of centerless grinding : through-feed centerless grinding, end-feed centerless grinding, and in-feed centerless grinding.

For centerless grinding of the outer diameter (raceway) of tapered rollers, which are rotationally symmetrical components, it is common to apply through-feed centerless grinding in consideration of mass production and high productivity.

Why it is so important to use Centerless Grinding?

Importance of Minimizing Centerline Change

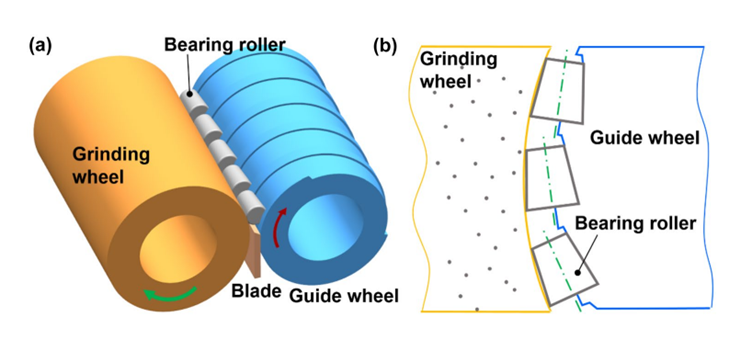

Unlike centered grinding, the centerline of the workpiece is not fixed in centerless grinding. Therefore, when the tapered roller moves along the width of the grinding wheel by the grinding drum, the dimensional change of the tapered roller according to the grinding allowance of the workpiece continuously changes the centerline of the tapered roller.

As a result, various efforts are being made to ensure the accurate setup of the grinding gap, select the appropriate workpiece speed, and perform proper dressing, all while minimizing any shifts in the centerline when the workpiece moves along the width of the grinding wheel.

But this is just a piece of the puzzle in producing high-quality tapered roller bearings! There’s another crucial aspect that we haven’t covered yet.

Are you curious? Don’t miss our next post and explore what comes next!

Written by Dennis Lee

Senior R&D Advisor

Editted by Yoonseung Han

R&D Associate

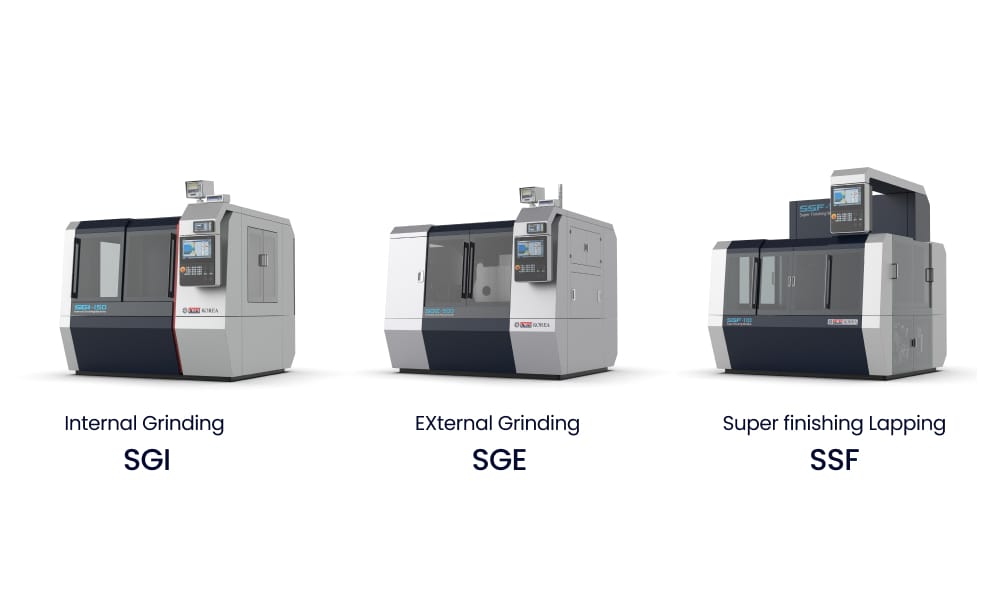

ORSKOREA is an ISO9001-ISO45001-certified company, and leading grinding machines and spindles manufacturer of Korea.

ORSKOREA's product range for grinding machines includes internal, external, centerless, surface horizontal double disc, surface vertical double disc, cylindrical grinding machines and super-finishing machines, turning machines, and special-purpose grinding machines.

For spindles, ORSKOREA manufactures high-frequency spindles, belt-driven spindles, built-in-motor spindles, and hydraulic spindles - all controllable at desired speeds.

For more information, sign up and join ORSKOREA community!