Insight | Tapered Roller Grinding #1 What's the Secret to TRB (Tapered Roller Bearing)?

1. What's the Secret to

Tapered Roller Bearing?

ORS Bearings has contributed to this improvement by producing 9 different types of bearings. ORSKOREA manufactures and supplies the grinding machines necessary for bearing production of ORS Bearings.

Then what types of bearings have shaped human history, and how are they made?

In this blog series, we will explore how Tapered Roller Bearings (a type of Roller Bearings) are made by the grinding process.

First of all, we’ll focus on what ‘Tapered Roller Bearings’ are, and the key grinding methods used in their production.

Tapered Roller Bearings

Tapered roller bearings(TRBs) are designed so that the imagined conical apices formed by the raceways of the inner and outer rings and the rollers all converge at one point on the bearing axis.

TRBs can take radial loads and axial loads in one direction.

When load is applied, the axial component generated inside the bearing generally requires the use of two opposed bearings (similar to angular contact ball bearings) or double-row bearings.

Spacers are used to adjust the inner and outer rings in the axial direction to achieve the proper internal clearance. Since they are separable, the inner ring (cone) assemblies and outer rings (cups) can be mounted independently.

[Ref. NSK]

ORS Bearing also produces tapered roller bearings, ORSKOREA provides grinding machines to produce high-quality bearings.

Tapered roller grinding process

In order to achieve the excellent quality and high precision of tapered rollers, which are the core components of tapered roller bearings, machining accuracy, surface quality, and batch consistency must be maintained.

The grinding process of the tapered roller may consist of several processes (steps), taking into account the precision grade of the tapered roller, the customer's quality requirement level and removal amount (grinding stock).

In the case of tapered rollers, unlike balls, the manufacturer operates its own precision grade

Customer's required quality level

Diameter difference of the tapered rollers in the tapered roller bearing, raceway roundness, raceway surface roughness, large end face radius dimensional accuracy, large end face runout

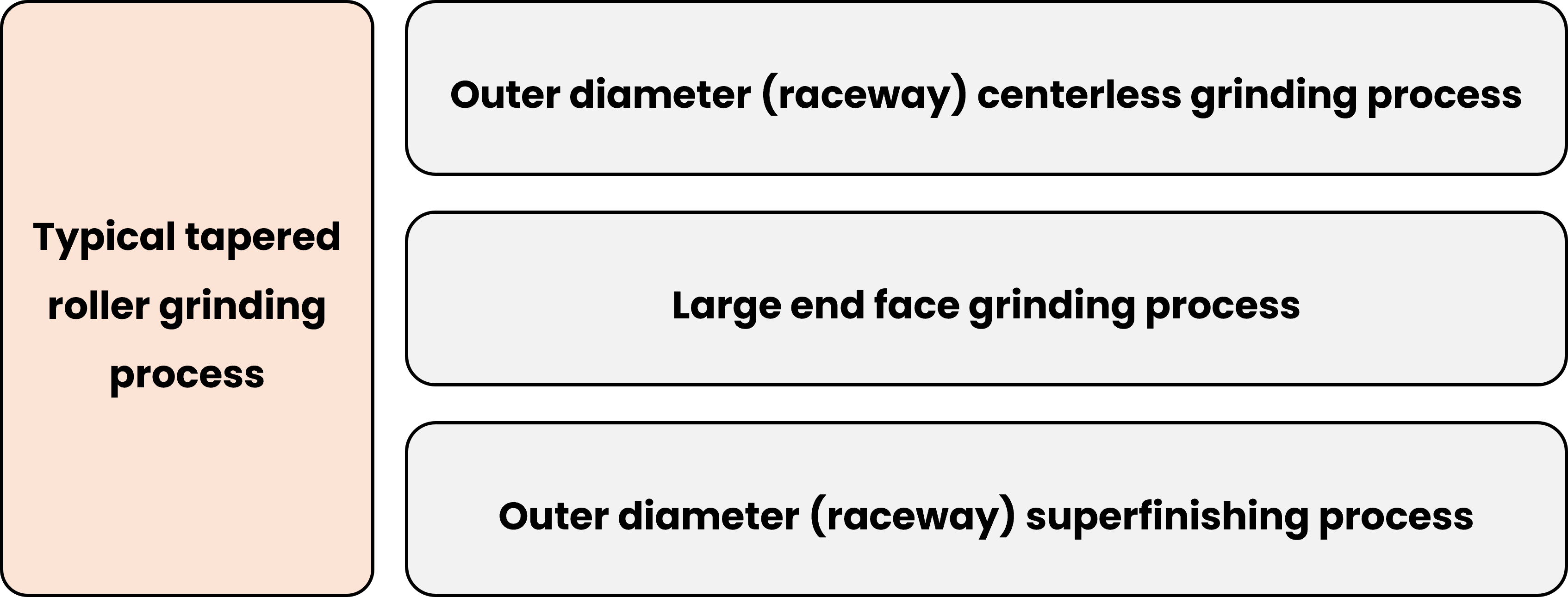

Typical tapered roller grinding process generally consists of a combination of the outer diameter (raceway) centerless grinding process, large end face grinding process and the outer diameter (raceway) superfinishing process.

The grinding processes of tapered rollers, such as the raceway centerless grinding process (rough + fine), the large end face grinding process (rough + fine, excluding plunge grinding), and the raceway superfinishing process, are mostly centerless processes, so it is very important to secure the rotational stability of the workpiece (tapered roller blank) during machining.

In addition, since the tapered roller large end face is processed based on the tapered roller raceway, and the tapered roller raceway is processed based on the tapered roller large end face, proper quality of the reference surface must be secured first.

In our next post, we’ll dive into more details about the centerless grinding, and important things to be considered during the grinding process.

Keep following along as we reveal the next steps in this exciting journey!

Written by Dennis Lee

Senior R&D Advisor

Editted by Yoonseung Han

R&D Associate

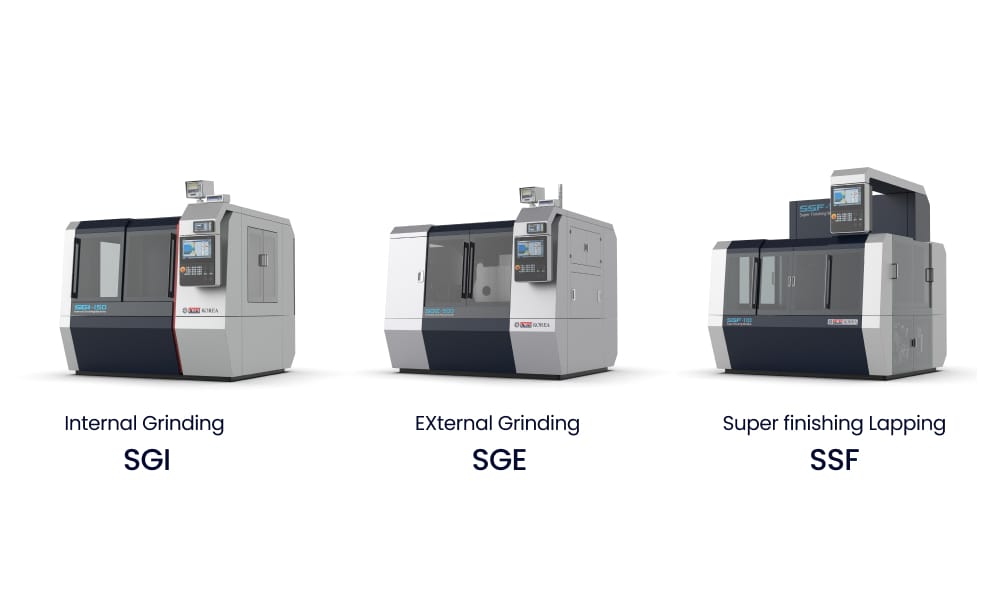

ORSKOREA is an ISO9001-certified company, and leading grinding machines and spindle manufacturer of Korea.

ORSKOREA's product range for grinding machines includes internal, external, centerless, surface horizontal double disc, surface vertical double disc, cylindrical grinding machines and super-finishing machines, turning machines, and special-purpose grinding machines.

For spindles, ORSKOREA manufactures high-frequency spindles, belt-driven spindles, built-in-motor spindles, and hydraulic spindles - all controllable at desired speeds.

For more information, sign up and join ORSKOREA community!

Want more information about Tapered Roller Grinding? Stay tuned!!